What Is a Static Line System?

Discover what a static line system is, how it works, and why it’s essential for ensuring safety during roof work and elevated construction tasks.

A static line system is a permanent or temporary cable-based fall protection system that allows workers to move safely along a fixed path while attached to a lifeline. It’s a key part of fall arrest and restraint programs for construction, maintenance, and industrial work at height.

Unlike a simple anchor point, a static line supports multiple users and enables continuous movement without disconnecting. Workers clip onto the cable using a shuttle or traveler that slides freely while maintaining attachment at all times.

This system reduces the risk of free fall and keeps operations compliant with OSHA 1910, ANSI Z359, and EN795 standards. Common applications include rooftops, bridges, and industrial maintenance zones.

How Static Line Systems Work

A static line system is made of a tensioned stainless-steel cable stretched between two anchor points. The user connects to the line with a lanyard and full-body harness. As the worker moves, the shuttle slides smoothly along the cable.

If a fall occurs, an energy absorber within the system dissipates force, preventing injury and protecting the structure. Systems can be designed for horizontal, vertical, or inclined surfaces, each calibrated to limit deflection and arrest forces.

For example, on a roof, a horizontal static line lets workers inspect gutters, vents, or solar panels without risk of falling off the edge. When tension is applied correctly, the system ensures safety while preserving freedom of movement.

Components of a Static Line System

A complete static line system includes several precision parts:

Anchors: Secure the cable to the structure.

Cable: Stainless steel or galvanized steel wire rope, tensioned to specification.

Shuttle or traveler: Allows user movement while staying attached.

Energy absorber: Reduces force in the event of a fall.

Intermediate brackets: Support long spans and limit cable deflection.

Harness and lanyard: Worn by the user to connect safely to the shuttle.

Each component must meet strict load rating and inspection criteria. Using certified components from brands like 3M, Guardian, Honeywell, or Kee Safety ensures compliance and long service life.

The Physics of Fall Arrest

When a fall occurs, gravity creates high kinetic energy. A well-engineered static line system manages that energy through load distribution and controlled deceleration.

Energy absorption: The absorber elongates to slow the fall.

Cable deflection: The line flexes slightly to reduce impact.

Anchor strength: Each anchor is rated to withstand fall loads, often over 5,000 lb.

Proper design ensures the fall arrest force transmitted to the worker remains below 1,800 lb, the OSHA limit. The result is a controlled, non-injurious stop.

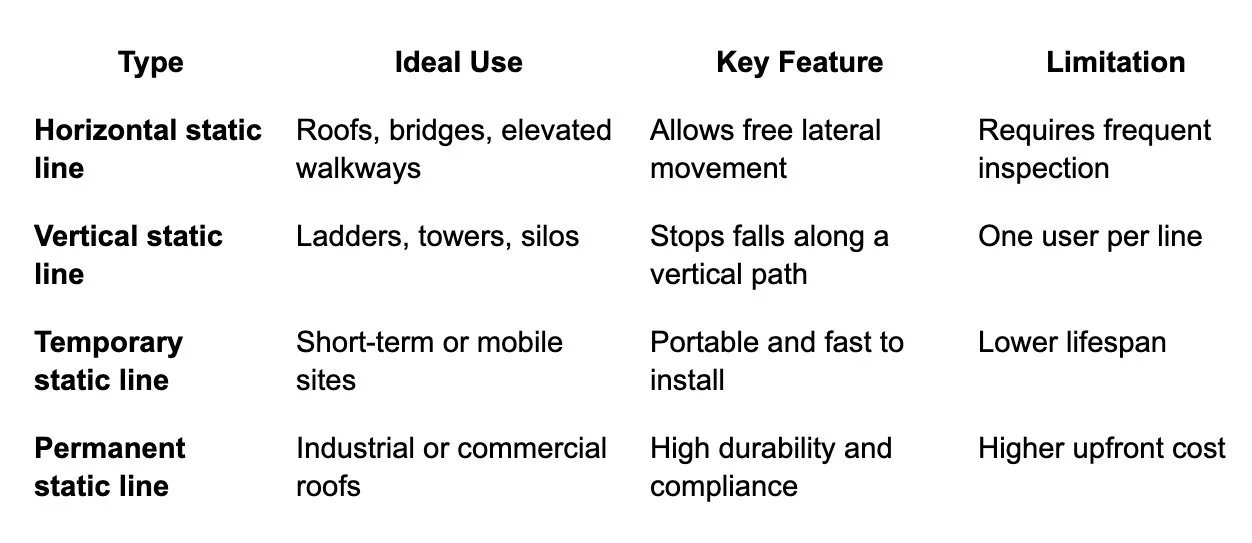

Horizontal vs. Vertical Static Lines

Choosing the right type depends on site design, frequency of use, and number of users.

Compliance and Standards You Must Meet

A static line system must comply with recognized safety standards.

OSHA 1910 & 1926: Governs general industry and construction fall protection.

ANSI Z359: Defines testing, performance, and design criteria.

EN795 (Europe): Specifies anchor device standards.

Employers are legally responsible for ensuring systems are installed, inspected, and certified by qualified professionals. Documentation, inspection tags, and training logs prove compliance during audits.

Installation Guidelines and Safety Protocols

Professional installation ensures reliability and compliance.

Basic steps:

Assess structure strength and anchor locations.

Mount end and intermediate anchors using approved fasteners.

Tension cable with a calibrated torque wrench.

Test line deflection and energy absorber response.

Record installation data for certification.

Follow a “zero gap” rule—workers must never detach while moving along the system. Annual recertification is recommended for all permanent systems.

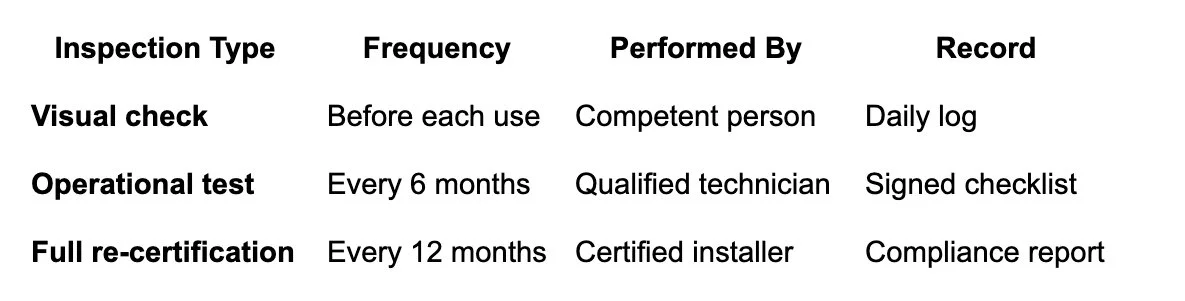

Inspection Schedule and Recordkeeping

Routine inspection keeps your static line system compliant and functional.

All inspections should include checks for corrosion, cable tension, loose fittings, and tag legibility. Maintaining a record of every inspection is a regulatory requirement under OSHA.

Cost, Value, and ROI of Static Line Systems

While the initial cost of a static line system can range from $2,000–$10,000, the ROI comes from long-term safety and reduced liability.

A compliant, low-maintenance system prevents costly injuries and downtime. Compared with temporary solutions or scaffolds, a static line provides a fixed, reusable, and audit-ready system that pays for itself over time.

Common Mistakes to Avoid

Using uncertified installers

Over-tightening cables beyond tolerance

Ignoring annual inspections

Mixing parts from different brands

Failing to train users on correct harness attachment

Each error increases risk and may void certification. Always work with a qualified fall protection engineer and follow the manufacturer’s documentation.

Real-World Applications and Case Studies

Roof Maintenance: Technicians access HVAC units safely without perimeter guardrails.

Bridge Work: Workers perform repainting and inspections while attached to fixed lines.

Industrial Facilities: Operators maintain conveyors and cranes with overhead static lines.

These examples show the flexibility of static line systems for any environment where fall hazards exist.

How to Choose the Right Static Line System

When selecting a system, evaluate:

Work area size and layout

Number of users per line

Substructure type (steel, concrete, wood)

Exposure to weather or corrosion

Compliance with OSHA and ANSI standards

For small projects, temporary horizontal lines offer flexibility. For large roofs or industrial settings, permanent systems deliver long-term protection and certification.

Integration With Other Fall Protection Equipment

Static line systems work best when paired with compatible harnesses, lanyards, and anchor connectors.

Ensure each component comes from an approved brand and matches load and certification standards. Integrating your system with a personal fall arrest system (PFAS) or overhead rail system provides total coverage for workers at every stage.

Conclusion and Next Steps

A static line system is one of the most effective ways to protect workers at height. It offers mobility, reliability, and compliance when properly installed and maintained.

To ensure your system meets safety standards:

Use certified installers

Keep inspection records current

Choose equipment that matches your site conditions